Lifemeta™ Tube Welder: Advancing Sterile Tube Welding in Biopharmaceutical Production

1, Feb 2024

In the dynamic landscape of the global biopharmaceutical industry, the widespread adoption of single-use product solutions in production processes has become a cornerstone. The need for achieving sterile and reliable welding of tubing on single-use products, including mixing bags and storage bags, is particularly crucial for processes relying on these innovative solutions.

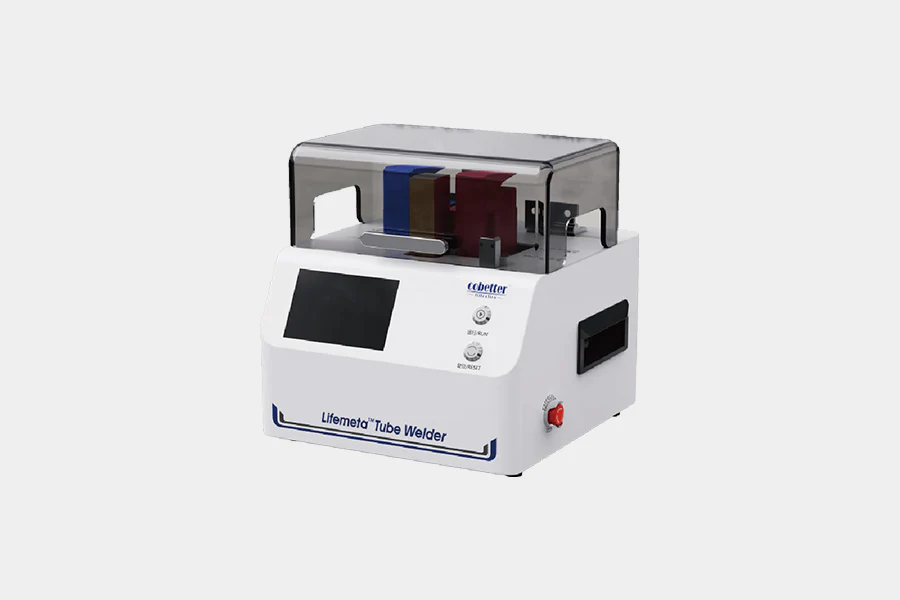

Introducing Lifemeta™ Tube Welder: A Sterile Revolution

Lifemeta™ introduces an automatic sterile Tube Welder meticulously designed for the welding of TPE tubing in single-use products such as liquid storage bags and sampling bags. This revolutionary device is not only suitable for welding dry, wet, or liquid-filled tubing but can also achieve sterile and reliable welding of TPE tubes even in non-sterile environments.

Key Features Setting Lifemeta™ Tube Welder Apart:

- Fast and Efficient: Leveraging quick temperature control, Lifemeta™ Tube Welder ensures that the welding process is completed in a mere 2 minutes, offering unparalleled efficiency in biopharmaceutical production.

- Economical and Flexible: With pre-set welding methods accommodating tubes of up to 8 different sizes, Lifemeta™ Tube Welder supports Lifemeta™ STF, C-Flex™ 374, and AdvantaFlex™ brand tubes. Additionally, it facilitates the process development of customizing other brands’ sizes, thanks to its special structural design catering to both liquid-filled pipes and empty tubes.

- Easy Operation: Equipped with an identification chip inside the tube holder, Lifemeta™ Tube Welder ensures quick and accurate connections, eliminating the risk of incorrect connections and streamlining the welding process.

- Safety First: The Tube Welder prioritizes user safety with a protective cover that automatically senses its position, effectively safeguarding users during operation.

- High-temperature Heat Source: Lifemeta™ Tube Welder stands out with its exceptional heating ability, reaching temperatures above 410°C, ensuring a thorough and effective heating process.

- Complete Verification Documents: Rigorously tested and validated, Lifemeta™ Tube Welder has successfully passed various tests, including pressure tests, tensile strength tests, water flow tests, bacterial challenge tests, extractable tests, insoluble particle tests, and endotoxin tests. The comprehensive verification documents underscore its reliability and quality.

Operating Steps for Seamless Tube Welding:

- Install the Tube Holder: Begin by securely attaching the tube holder onto the device.

- Secure Tubes: Sequentially secure the tubes within the Tube Welder.

- Blade Installation: Install the blade, ensuring the temperature sensing point faces the temperature sensing plate.

- Cover Closure: Close the upper cover securely.

- Initiate Welding: Start the welding process by pressing the ‘Run’ button.

- Quality Inspection: After completion, remove the welded tubes for a thorough quality inspection.

- Reset Process: Press the “Reset” button to reset the Lifemeta™ Tube Welder for subsequent operations.

Versatile Tube Compatibility with Lifemeta™ Tube Welder:

- Lifemeta® STF

- C-Flex®374

- AdvantaFlex®

Tube Sizes and Holders:

The Tube Welder accommodates a variety of sizes with corresponding tube holders, ensuring compatibility and flexibility in various applications.

Ordering Information:

- Lifemeta™ Tube Welder: LMTWA0 (1 pcs)

- Blade: SH20 (50/box)

- Tube Holders in different sizes and configurations (2 pcs/group)

In conclusion, Lifemeta™ Tube Welder emerges as a groundbreaking solution, addressing the critical need for efficient, sterile, and reliable tube welding in the biopharmaceutical industry. Its features, coupled with ease of operation and robust safety measures, make it an indispensable tool for advancing the production processes reliant on single-use solutions. With Lifemeta™ Tube Welder, pharmaceutical companies can elevate their standards, ensuring the integrity and quality of their processes in a rapidly evolving industry.