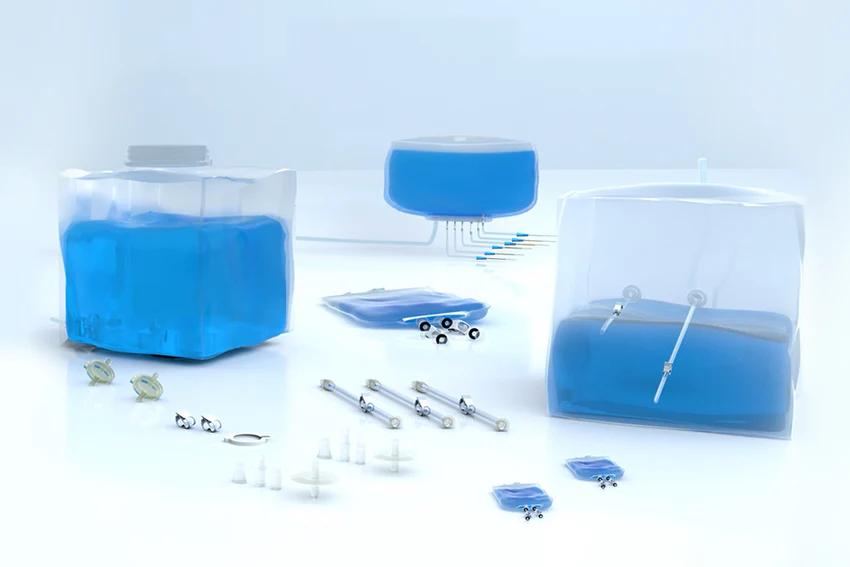

Antibodies, also known as immunoglobulins (Ig), are essential glycoproteins capable of specifically binding to antigens. This property makes them invaluable in various therapeutic and diagnostic applications. Common antibodies include monoclonal antibodies, bispecific antibodies, polyclonal antibodies, ADCs (antibody-drug conjugates), and FC fusion proteins. In the complex and sensitive production process of these antibodies, speed and cost-efficiency are critical. To achieve these goals, the industry increasingly relies on single–use systems. These systems streamline processes such as culture media preparation and filtration, cell cultivation, harvesting, clarification, buffer preparation and filtration, ultrafiltration, purification chromatography, and formulation filling.

Application of Single-use Systems in Antibody Production

Upstream Applications

- Preparation, Filtration, and Storage of Culture Medium: Ensures a sterile environment for cell growth.

- Cell Culture: Utilizes disposable bioreactors to minimize contamination risk.

- Sampling of Fermentation Broth: Allows for sterile sampling without compromising batch integrity.

- Harvesting of Fermentation Broth: Efficiently separates cells from the broth.

- Harvesting after Centrifuge or Depth Filtration: Prepares the cell mass for downstream processing.

Downstream Applications

- Buffer Preparation, Filtration, and Storage: Maintains buffer purity and sterility.

- Virus Inactivation and Clarification Filtration: Ensures safety and efficacy by removing viral contaminants.

- Purification Chromatography and Material Harvesting: Optimizes the separation and collection of target antibodies.

- Virus Removal, Sampling, and Material Harvesting: Further purifies the product by removing residual viruses.

- Ultrafiltration Concentration and Liquid Exchange: Concentrates the antibody solution and facilitates buffer exchange.

- Sterile Sampling Process: Maintains product sterility throughout processing.

Among these, the chromatography process is particularly time-consuming and labor-intensive due to the need for disinfection, balance, rinsing, elution, and liquid exchange. Single-use systems for liquid preparation, storage, and chromatography harvesting significantly enhance production efficiency and process optimization.

Chromatography Process

Preparation Process

Appropriate liquid dispensing systems are selected based on buffer volume and process requirements. The process may involve more than 17 types of buffer solutions, primarily comprising 1000L disinfectant buffer, 2000L equilibrium buffer, 1000L wash buffer, 1000L elution buffer, and 500L preservation buffer, used in a three-step chromatography process. Real-time monitoring of pH, conductivity, and other parameters is achieved through online electrodes, ensuring precise data recording during liquid preparation.

Filtration Process

Capsule filters, made from materials such as PES and PVDF, can be pre-assembled with the preparation and collection systems. Post-irradiation sterilization, these filters are ready to use, eliminating the need for additional sterilization and assembly. This reduces high labour costs and minimizes risks like mis-operation and bacterial contamination, enhancing overall safety.

Intermediate Product Harvest

The chromatography harvesting process directly connects the chromatography system outlet to the mixing bag, allowing mixing to start during harvesting. Equipped with a temperature control sleeve, the system can maintain temperatures between 2-8℃ if required. The method of membrane chromatography further streamlines production by integrating the capsule filter and harvesting system.

Ultrafiltration System Integration

Single-use liquid dispensing systems replace traditional ultrafiltration buffer tanks. With a bottom drain design, these systems allow thorough drainage, shorter pipelines, and smaller circulating dead volume compared to stainless steel systems. The automatic control unit of the single-use mixing system can integrate with the ultrafiltration system’s control unit, reducing hardware investment and simplifying operation.

Application in Antibody Production Formulations

- Dosage Preparation: Ensures accurate formulation and preparation of antibody doses.

- Filtering and Filling: Maintains sterility and precision during the final filling process.

The preparation stage emphasizes cleanliness, system design, and operation, involving sterile transfer of materials. The filling stage focuses on the filling pipeline, filling needle, liquid properties, and equipment compatibility, ensuring the stability of the filling volume.

The rapid development of antibody drugs has made speed and cost-efficiency crucial. Cobetter’s comprehensive range of filtration and single-use products are designed to meet these demands, ensuring high-quality, cost-effective biopharmaceuticals for patients worldwide. By leveraging Cobetter’s innovative solutions, antibody manufacturers can optimize their production processes, reduce costs, and maintain the highest standards of product quality.