Ensuring virus safety is a top priority in biopharmaceutical manufacturing, especially in the production of recombinant human erythropoietin (rhEPO). Viral contamination poses significant risks, dictating robust filtration and clearance strategies. Cobetter Viruclear™ VF Filters have emerged as a reliable solution for virus removal, providing high efficiency and preserving the physical and integrity of the target protein.

This article explores the critical role of Viruclear VF Filters in the virus removal filtration process for rhEPO, analyzing real-world case studies and discussing optimal filtration strategies.

Understanding Erythropoietin (EPO) and Its Production Process

Erythropoietin (EPO) is a vital hematopoietic growth factor responsible for red blood cell production. It prevents myelocyte apoptosis, stimulates the release of reticulocytes, and enhances intracellular protein synthesis. Due to its essential role, recombinant human EPO (rhEPO) is widely used for treating anaemia in patients with renal insufficiency, AIDS, malignancies, and other conditions.

Recombinant Human EPO Production

The rhEPO production process primarily relies on Chinese hamster ovary (CHO) cells. Genetic engineering techniques enable the insertion of the EPO gene into CHO cells, which are then cultured to express the protein. However, the use of CHO cells introduces potential risks of viral contamination, requiring stringent virus clearance measures to ensure product safety.

The Importance of Virus Removal in rhEPO Production

Regulatory guidelines demand the implementation of multiple virus clearance methods to eliminate contamination risks. Among various approaches, chromatography and nanomembrane filtration are the most effective. Virus removal filtration, in particular, stands out for its high viral load reduction (LRV) efficiency, minimal impact on protein structure, and compatibility with high-concentration formulations.

EPO Process Filtration Using Cobetter Viruclear VF Filters

Case Study 1: Low-Concentration EPO Filtration

Conditions:

EPO Concentration: 1.59 g/L

Prefiltration: PTD and PNY prefilters separately

Virus Removal Filtration: Cobetter Viruclear VF Plus at 30 psi

Results:

PTD + VF Plus: Recovery rate 97.7%

PNY + VF Plus: Recovery rate 99.2%

Case Study 2: Medium-Concentration EPO Filtration

Conditions:

EPO Concentration: 49 g/L

Prefiltration: PTD and PNY prefilters separately

Virus Removal Filtration: Cobetter Viruclear VF Plus at 30 psi

Results:

PTD + VF Plus: Recovery rate 97.3%

PNY + VF Plus: Recovery rate 99.0%

Case Study 3: High-Concentration EPO Filtration

Conditions:

EPO Concentration: 89 g/L

Two-Test Groups:

Prefiltration with PTD → Tested with Cobetter Viruclear VF Plus at 30 psi

Prefiltration with PNY → Tested with Cobetter Viruclear RC H at 29 psi

Results:

PTD + VF Plus: Recovery rate 97.9%

PNY + RC H: Recovery rate 99.8%

Choosing the Right Filtration Solution for EPO Processing

Cobetter Viruclear VF Plus is the recommended filter for low-concentration and low-fouling EPO materials due to its high efficiency and recovery rates. For high-protein concentration and high-fouling materials, Cobetter Viruclear VF Plus X or RC H virus removal filters provide superior performance.

Selection of Prefilters

PNY Nylon Prefilter: Best for minimizing attenuation during filtration.

PDT Depth Filter: Suitable for applications requiring attenuation but with potential protein adsorption, necessitating careful yield evaluation during process development.

Advancements in Virus Safety and Filtration Technology

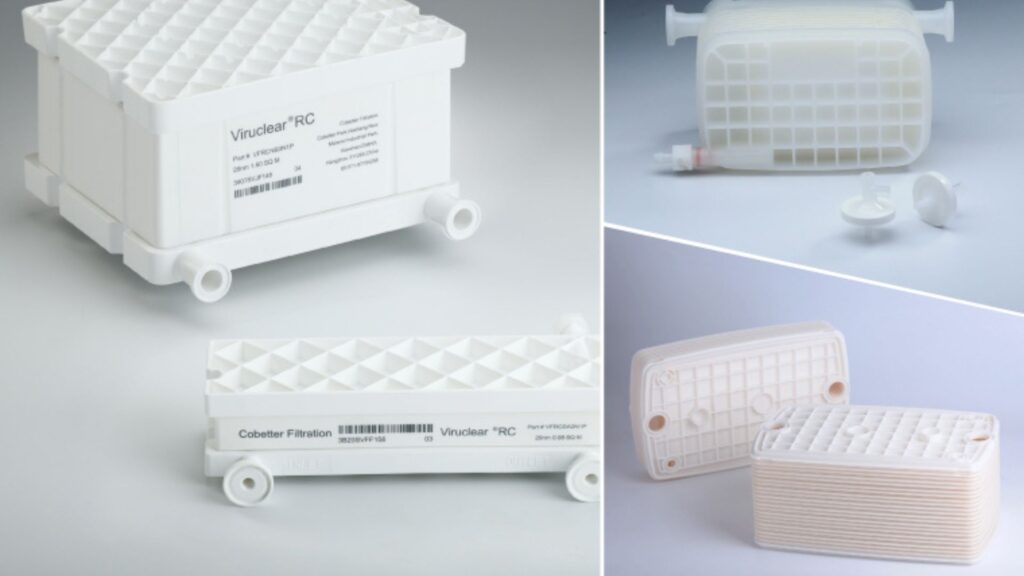

Ensuring virus safety in biopharmaceutical production requires a comprehensive evaluation of the removal process. Cobetter has introduced three PES (polyethersulfone) virus removal filtration products and two RC (regenerated cellulose) virus removal filters with prefilters to meet the highest safety standards in biological product manufacturing.

Moving forward, Cobetter remains committed to improving membrane filtration technology, optimizing filtration performance, and improving product stability. The focus is on increasing filtration capacity while reducing costs, ensuring reliable and efficient solutions for the biopharmaceutical industry.

Virus removal is a critical aspect of rhEPO production, and Cobetter Viruclear VF Filters play an essential role in achieving high virus clearance efficiency, minimal protein loss, and regulatory compliance. By selecting the appropriate filtration system, manufacturers can ensure the safety, efficacy, and quality of recombinant EPO products.

For more information on Cobetter’s advanced virus removal solutions, visit Copure website, www.copure.com.au, and explore case studies demonstrating filtration performance in real-world applications.